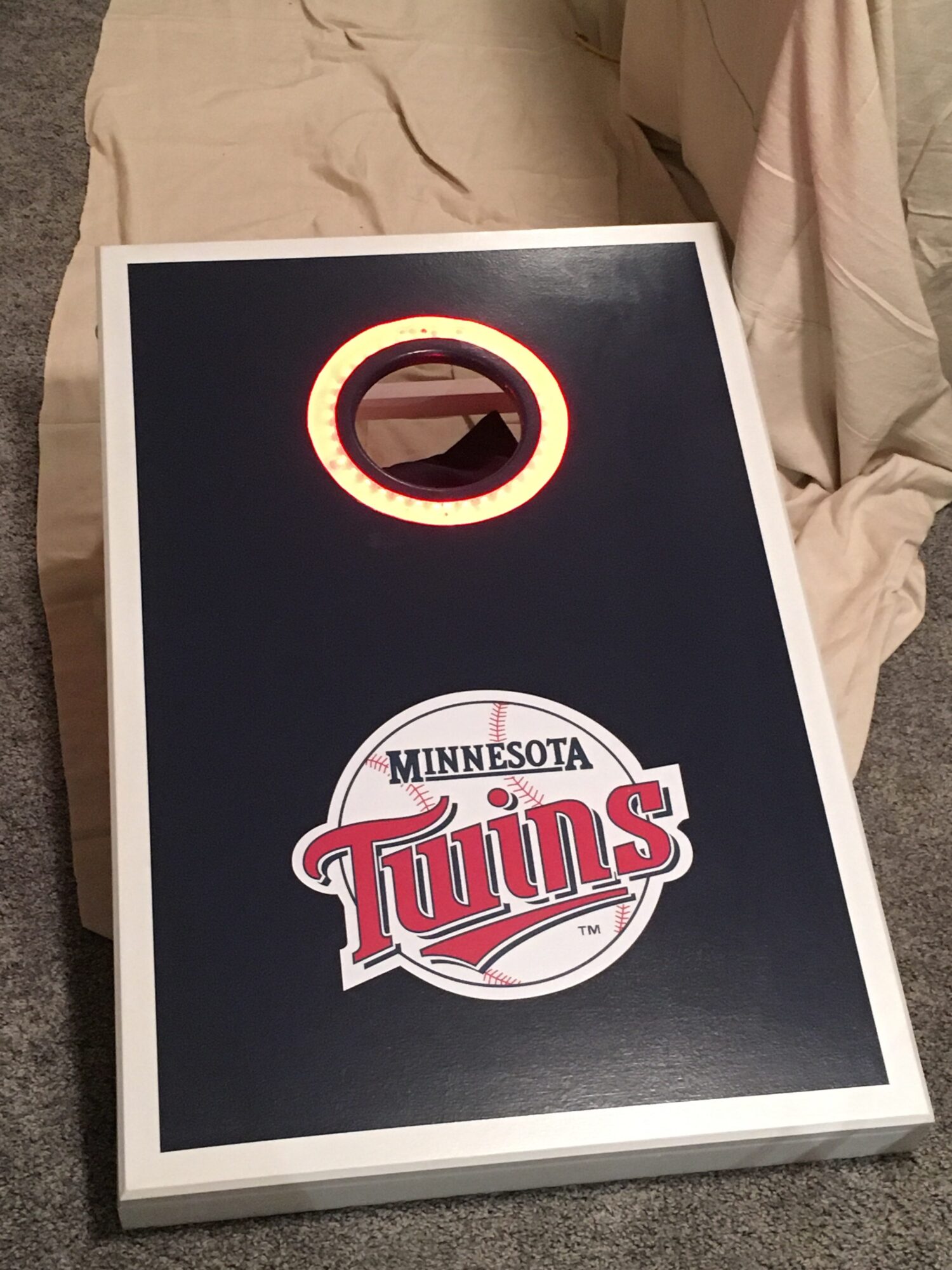

A while ago I got my hands on some scrap photoelectric sensors from work. The defects were only cosmetic, so I mounted a pair of them to a flimsy bean bag toss (aka cornhole) set I had made a couple months before. I drilled 12 small holes in a circle around the main hole and filled them with LEDs. I added a little box with some batteries and a couple 555 timer circuits so that the LEDs would flash for a few seconds whenever a bag went through the hole. The effect was kinda cool considering it was mostly just slapped together from parts in the junk bin. I could’ve left it at that, but why settle for kinda cool when you could spend a bunch of time and money over-engineering it to become something that’s mostly the same, but just a little better?! So, a friend and I did just that…

Let there be light

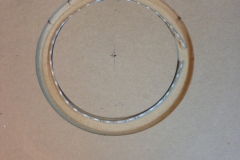

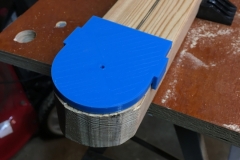

Because the discrete LEDs where just hot-glued into holes in the board, they were hard to see in daylight, especially if you weren’t looking head-on. To fix this, we embedded a strip of LEDs from (the very accurately named) superbrightleds.com into a groove in the bean bag board and filled it with epoxy. The epoxy was a pain to work with, but it diffused the light nicely (see above) and could be planed flush with the surface so that it didn’t interfere with game play.

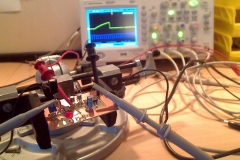

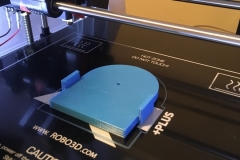

Fresh PCBs baking in the oven

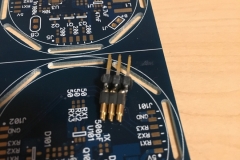

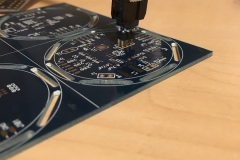

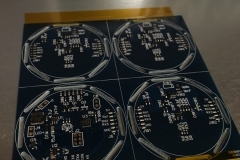

The next issue was the electronics. If we were ever going to make more than one of these sets, we’d need to somehow keep sourcing scrap sensors. Instead, we opted to design our own photoelectric detection circuit, order some PCBs, and reflow the SMT parts in a toaster oven.

The rest of the build

At some point I’d like to fill in the details, but for now here’s a time-lapse and some haphazard photos of the rest of the build.